How to achieve a competitive advantage through Distribution Networks

After the lesson on distribution networks, I researched to complete the training a bit more and I found how to obtain efficiency on the distribution.

“The success in the market and the competitive advantage depend on distribution network”

Without efficiency in distribution networks, the success in markets and obtaining a competitive advantage could not be achieved. This is why it’s necessary to get a balance between the maximizing customer service, the minimizing transaction costs, the investment made and the risk. A solid strategy is vital to align the decisions and actions with the objectives, but at the same time, it’s interesting to take into account some of the principles applicable to the design of the distribution networks, beginning in its preparation stage, where the bases for efficiency are laid.

Previous steps in the design of distribution networks

Before defining the applicable model of distribution networks and their different scenes, it’s essential to start with these 6 steps:

ONE.

Definition of the scope

It’s crucial not to lose alignment with the evolution of the business and the transformations that implies. The distribution chain and its processes must adapt to the sales volume, the number of customers, the variety of products, the different markets where it works, the particularities of the business and the requirements applicable to operations.

TWO.

Identification of the limitations

Every project suffers from restrictions and especially talking about the logistics chain. Storage capacity, budget limits, handling requirements of each product, transport conditions, availability or risk tolerance, among others.

THREE.

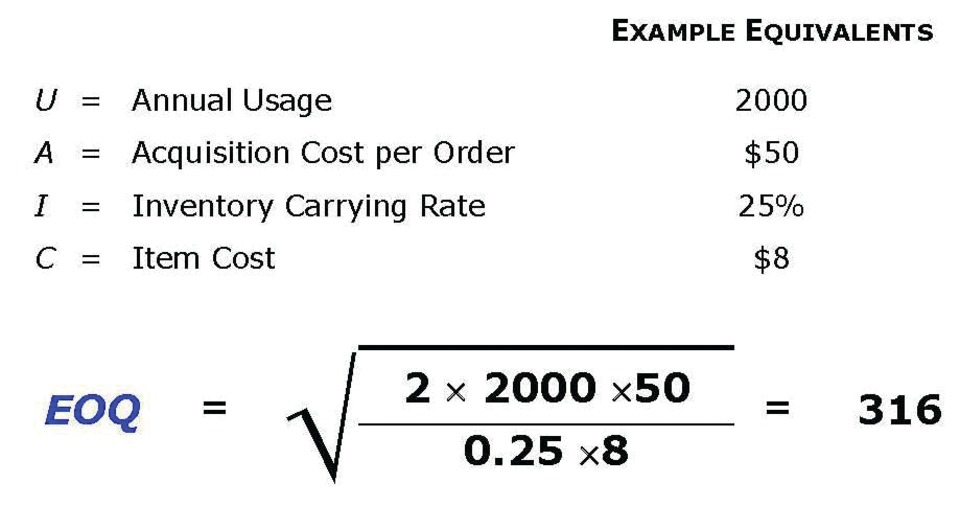

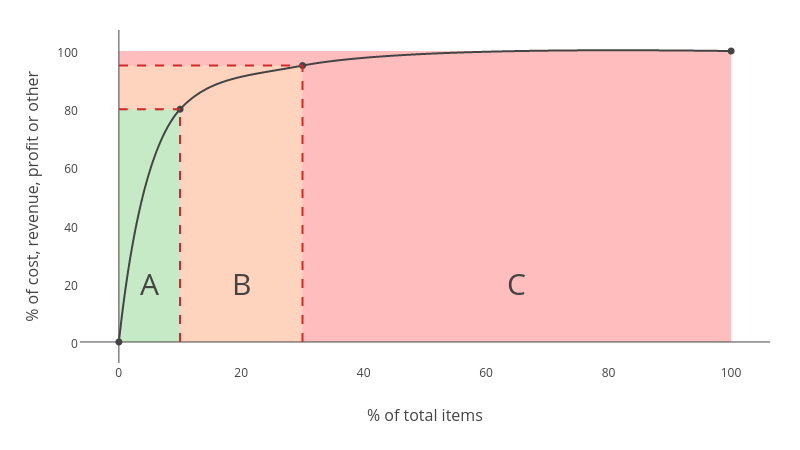

Establishment of objectives

Justifying the investment and adapting to the service requirements. The objetives must be concrete, achievable and realistic. Generally, are grouped into two categories, goals related to the reduction of costs and strategies related to improving the service. Among the former, the rationalization of inventories, the minimization of storage costs, the reduction of transport costs or the adjustment of labor costs are frequent; On the other hand, the latter refer to performance or the flexibility.

FOUR.

Study of the environment

This analysis allows to detect opportunities and threats. Being a hard struggle, which implies a high consumption of effort and resources, it is a necessary step for the elaboration of the strategy and the optimization of the design of the distribution networks. Among the data collected, are the complete description of the distribution goods, the historical records of operations, the applicable transport rates and their conditions, the addresses of suppliers and customers, the service requirements and the applicable legal regulations.

FIVE.

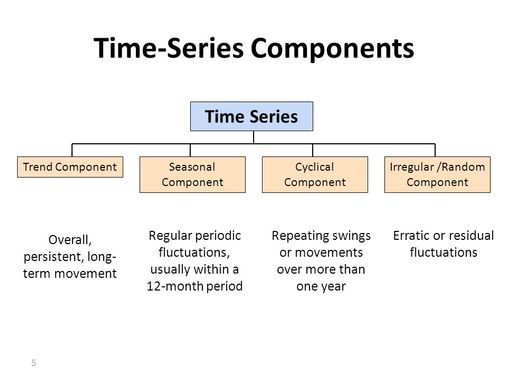

Forecasting

Must be carried out in order to forecast the growth of demand, inventory needs and trends that will influence the management of the distribution chain; so that the actions to be taken can be planned.

SIX.

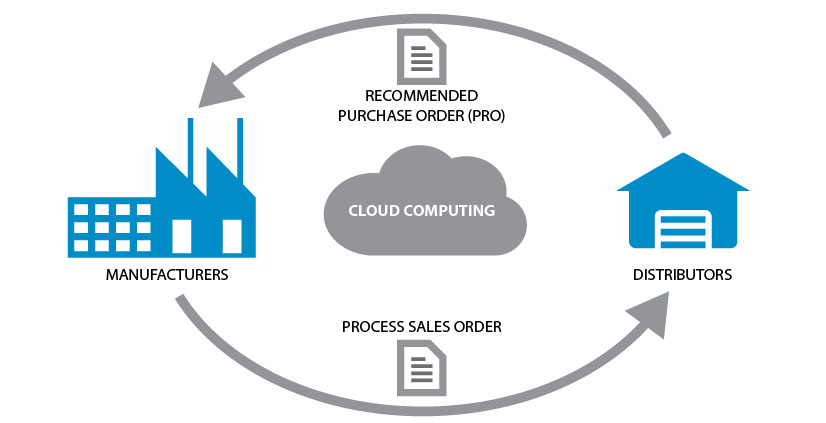

Selection of distribution network design tools

In the market there are different possibilities of solutions to design a network of this type. In the election, it should find that the selected tool includes softwares with database analysis capabilities, calculations applicable to transport optimization, specific applications aimed at innovation to improve customer service or simulators that allow greater dynamism and precision in decision making.

With these steps we can design an optimized distribution network model that will always be subject to revision, to guarantee its updating and suitability in the business conditions.