Immersive technologies are transforming the way of doing business through virtual, augmented, and mixed reality, which companies are implementing in different areas, such as Sales, Logistics and Mantainance.

This technology applied have great potential in companies, and Daniel Iribarren and his team knows it, dedicated for more than 8 years to bring virtual and augmented reality solutions for efficiency and safety in the industrial sector through their company IMOVA, which has been developing solutions with immersive and gamification technology to help businesses to train employees and improve operational efficiency. Since 2019 their Spinoff GOT IT, has specialized in operations management, delivering solutions that improves efficiency in logistics, maintenance, and security, ranging from providing remote assistance in real time, to “vision picking”, in which big players in Logistics Industry are taking part, such as DHL or Wallmart.

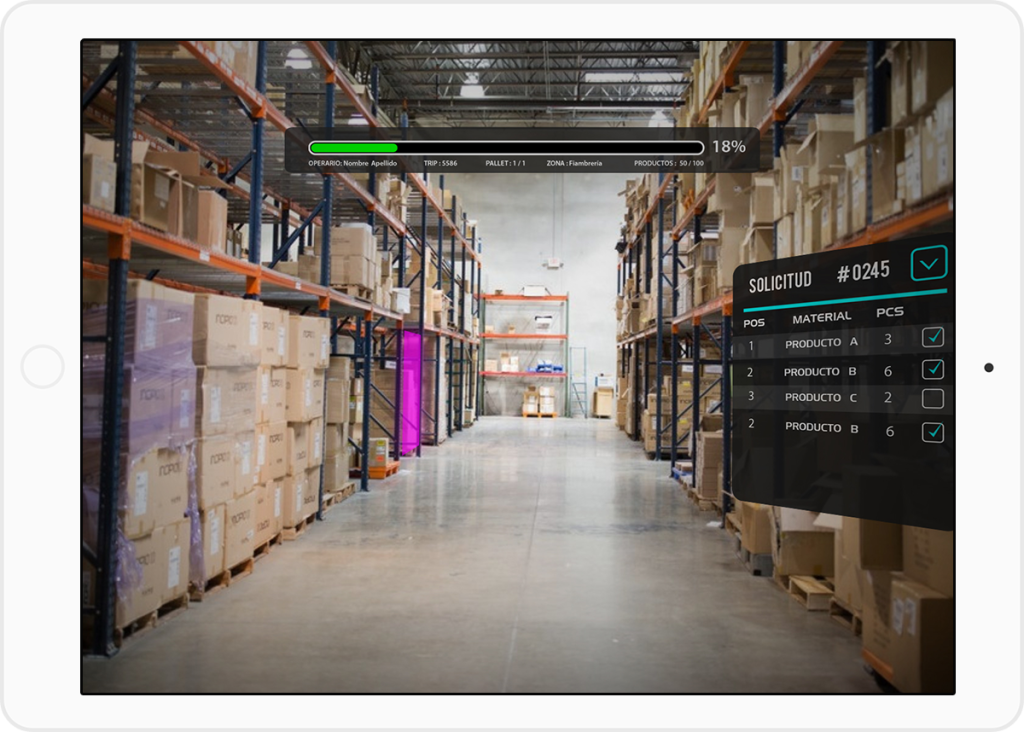

Picking and packing tasks in warehouses, can be improved by reading with Augmented Reality glasses, that have a special card which contains information like order number, code of the product to be collected, its location in the warehouse, in which basket / dispatch of the cart it must be placed, progress, among others. In this way, the operator can carry out his activities faster, without repetition and reducing errors, improving efficiency up to 25% according to a DHL trial developed in Netherlands. In addition to the order storage system using Augmented Reality vision, the report from DHL describes the best practices and use cases of this technology in logistics.

Other relevant topic for Logistics is Safety, especially in warehouses or other facilities where machinery is manipulated by operators and have risk of accidents, which can end fataly. Training through virtual reality can help operators to identify risks, retain information, reduce onbonarding times and improve their skills and productivity. In this video a Demo developed by IMOVA to see how a training for a forklift operator using VR Glasses would look like.

Personal approach

Using virtual reality and augmented reality aplications for sales area, places, products, equipment or machinery can be shown interactively and with all detail needed, for example, the interior of an engine, the detail of any product you are looking at or the interior of a house which has not yet been built.

My personal experience from Chile, while working in real estate and hospitality companies in marketing and sales area, I have learned to use VR to show houses, hotel rooms and buildings remotely, which is especially useful for a first approach to the customer in the sale process, when the project is in a different location from the client or is in an early stage of the construction, helping them to understand better the distribution of the space and interact in diferent levels.