The Internet of Things is connecting more and more devices every day, industries are implementing IoT to improve their efficiency and decision making. The number of connected devices in 2017 was larger than the global population with more than 8.4 billion.

Logistic companies like DHL are using IoT, to access to information of their workers to provide a safe working environment. Also companies with different types of distribution network, retail, wholesales, last mile, drop-off, like Walmart, Costco, Mercadona and Amazon, are implement IoT to take advantage of the data.

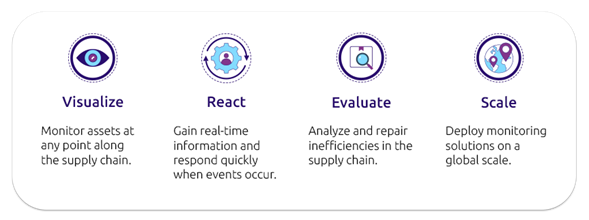

The IoT can be used in different sectors,this will improve the visibility and monitor the location of goods, people and trucks. The IoT improves the asset management, delivery, and supply chain, will provide the analytics to generate information, predictability and new business value and revenue.

Poh Khai, Senior Innovation Manager, at DHL said: “By exploring the use of IoT across our warehousing, logistics, and transportation systems, we can analyze the data generated at every critical point to identify ways to better manage inventory, better predict system maintenance, and better monitor and control supply chains. …. It strengthens our ability to ‘sense’ and improve our environment, turning data into valuable and actionable insights”

For more information, you can visit these articles

https://lot.dhl.com/harnessing-the-power-of-iot-for-the-logistics-industry/