In our society today, environmental awareness plays a big role. For example the food production should be sustainable, plastics bags are banned from some stores in order to reduce waste and cars should have lower or even no (electric cars) emissions in order to be attractive to most customers. This “green” movement also has an impact on today’s logistics.

In general, the term green logistics describes a supply chain in which all activities are coordinated and carried out in such a way that their effect on the environment is as low as possible. The areas that are addressed include the means of transportation, the disposal of waste and residual material and the packaging which also makes the consumers’ contribution necessary since they are responsible for disposing and recycling a product’s packaging.

In regard to transportation this could start with just choosing the most efficient way to transport the goods, e.g., don’t drive with a half empty truck, but could also go as far as only using “green vehicles” for the transportation.

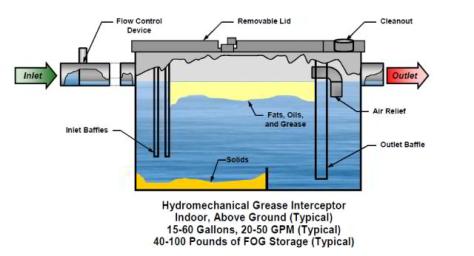

Also, during the production, green logistics includes efforts that are made in order to reduce the water consumption and keep it at a minimum by for example recycling processes that enable to reuse the water several times. Sometimes, the production of goods (or the maintenance of vehicles and machinery) also results in water that also includes oil/grease, fuel and other waste that could harm the environment if this water is simply released into nature. To avoid this pollution, the installation of “interceptor tanks” can be helpful (see picture below).

This picture shows a simple version of such an interceptor tank or grease trap. The dirty water comes in on one side and several barriers are installed to stop the unwanted material. On the bottom, the solid particles accumulate and are then stopped by one of these barriers. At the same time, all fats and the fuel rise to the top and will float on the water due to their lower density and are also stopped by a barrier that is installed on the “ceiling” of this tank. The now relatively clean water continues to flow to outlet and exits the tank leaving all the unwanted stuff behind. This is one example of how a simple method can be used in order to make a production site more “green” and environmental friendly. This was just a small insight into “Green” logistics since it, of course, covers a much broader area and this blog would have to be way too big to describe it all in detail.

(Source for information of this blog: http://dlca.logcluster.org/display/LOG/Green+Logistics & https://www.glanvilleenvironmental.com/services/construction-civil-engineering/interceptor-tank-installation-drainage-sewer-diversions-manhole-construction/)