The exponential growth of e-commerce is accompanied by the constant search for supply chain optimizations that lead to shorter delivery times. One valuable strategy in this never-ending pursuit is cross-docking: a logistics practice that involves receiving goods from suppliers and immediately transferring them to outbound transportation, without the necessity for long-term storage. In the e-commerce context, this dynamic becomes extremely valuable due to the need for fast order fulfillment. Bypassing the traditional warehousing and reducing the handling time, cross-docking makes a faster movement of products from suppliers to clients possible, minimizing lead times and increasing the efficiency of the operations.

In e-commerce, quick and reliable order fulfillment is a key differentiator. Cross-docking allows businesses to expedite the process by minimizing the time between order placement and delivery of the product. The dynamic ensures that items are rapidly dispatched to customers and fulfill their expectations for shorter delivery times, as they are received, sorted and quickly transferred to outbound shipments. This efficiency and agility contribute to increase customer satisfaction and loyalty.

Furthermore, while traditional warehousing leads to substantial associated costs towards inventory holding, storage space and stock levels management, cross-docking minimizes the necessity for long-term storage, reducing inventory holding costs for e-commerce business and improving their cash flows.

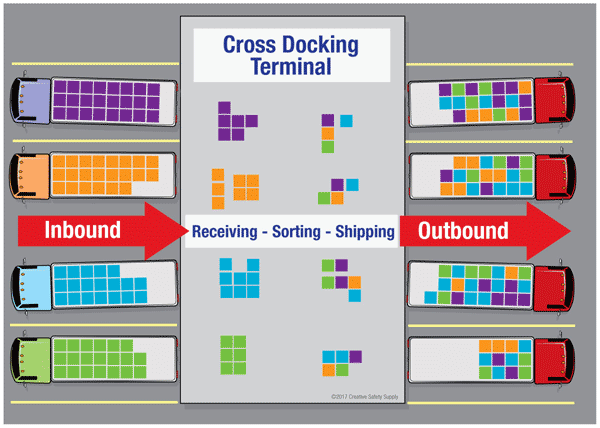

Cross-docking scheme, by Creative Safety Supply.

Nevertheless, efficient cross-docking requires robust information systems and real-time visibility across the supply chain. In other words, advanced technologies, such as Radio-Frequency Identification (RFID) and integrated software solutions must be used to provide e-commerce companies with comprehensive visibility into the movement of the products across the cross-docking network. This visibility is necessary for better planning, monitoring and coordination needed for an improved inventory management with less errors in order processing.

In the fast-paced world of e-commerce, the supply chain optimization is a priority. Improving the cross-docking network provides a solution to streamline operations, accelerate order fulfillment, reduce inventory holding costs and enhance overall customer satisfaction. By adopting advanced technologies and embracing real-time visibility, e-commerce businesses can unleash the potential of cross-docking and achieve competitive advantages.