Last class, we were focused on how to design a warehouse. For this reason, I wanted to write a post compiling some elements that should be taken into account when designing one.

When designing a warehouse, some questions may come to your mind: How should a warehouse or distribution center look like? What factors influence the warehouse layout plan? What goals should the warehouse design achieve? What is the best way to set up a warehouse layout? In this post, I will try to respond to these inquiries.

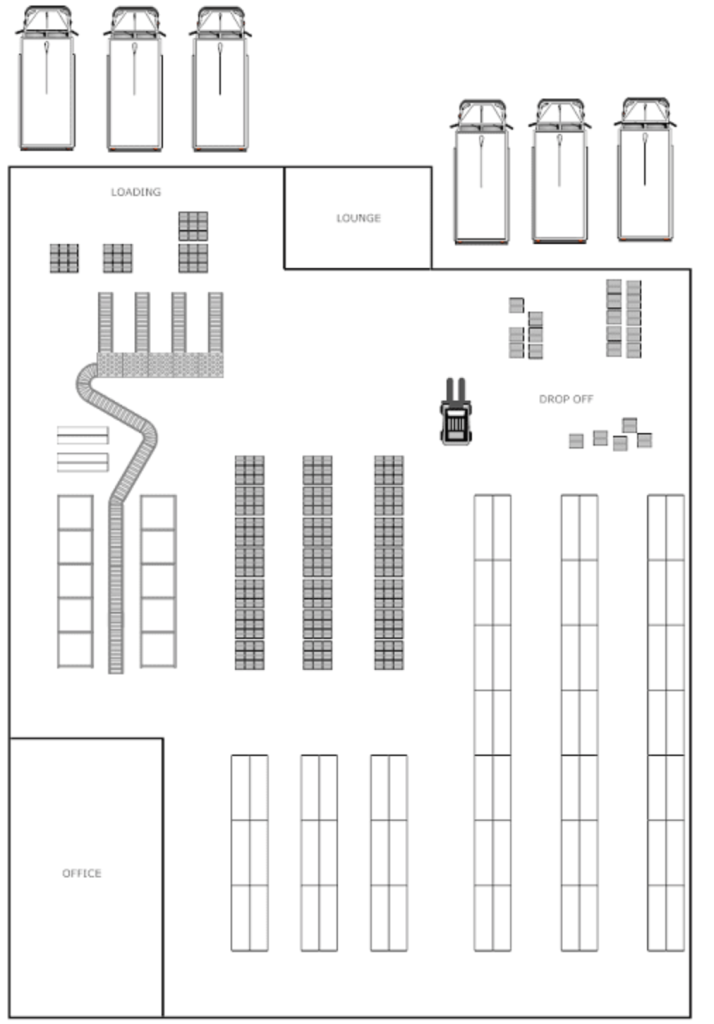

The process of distributing both the external and internal space of the facility shown on a plan is referred to as warehouse design or layout. It should represent the most efficient method of managing the stocks that will be stored there and the following elements must be included: The warehouse’s interior and external layout, the total number of levels, principal installations and its areas. As an example, here we can see one:

As factors that influence the warehouse layout plan, the following ones should be determined:

- Merchandise flow in the warehouse (the sequence of actions required by stocks or the manufacturing process).

- Rotation of products (how frequently different sorts of commodities in the inventory must be replaced over time).

- Desired stock level (keeping storage costs to a low while serving client demand).

- Product requirements (types and quantities of each tool that will be required for efficient operation in the work area).

- Essential stuff (also providing safety and training).

When all these factors are in place, the following objectives should be met:

- Space optimization in the warehouse.

- Removal of any processes that aren’t adding value.

- Improve the flow of commodities and people information, also providing flexibility and facilities for the access and control of product units.

- Increase of profitability.

Finally, for considering the different types of warehousing configuration, here I upload a video that explains three different types of flow options: U-shaped option, I-shaped option and L-shaped option. For each of the options, the advantages and disadvantages of implementing them are explained:

Source: https://www.youtube.com/watch?v=0OeStxbzKsM

Resources:

10 Great Warehouse Organization Charts