During the pandemic period, customers have been forgiving delays and problems in the supply chain, but this goodness will not last forever. To lead the market and be competitive, it is necessary to put customers at the centre of operations, this is called customer centricity.

Customer centricity consists in carrying out a series of actions focused on satisfying the needs and desires of customers. To do this, it is necessary to adapt to each type of customer, segmenting them in order to define specific strategies that are adjusted to each type of client. More specifically, the customer-focused supply chain refers to the improvement of the customer experience in the delivery process, i.e. warehousing, distribution and after-sales service.

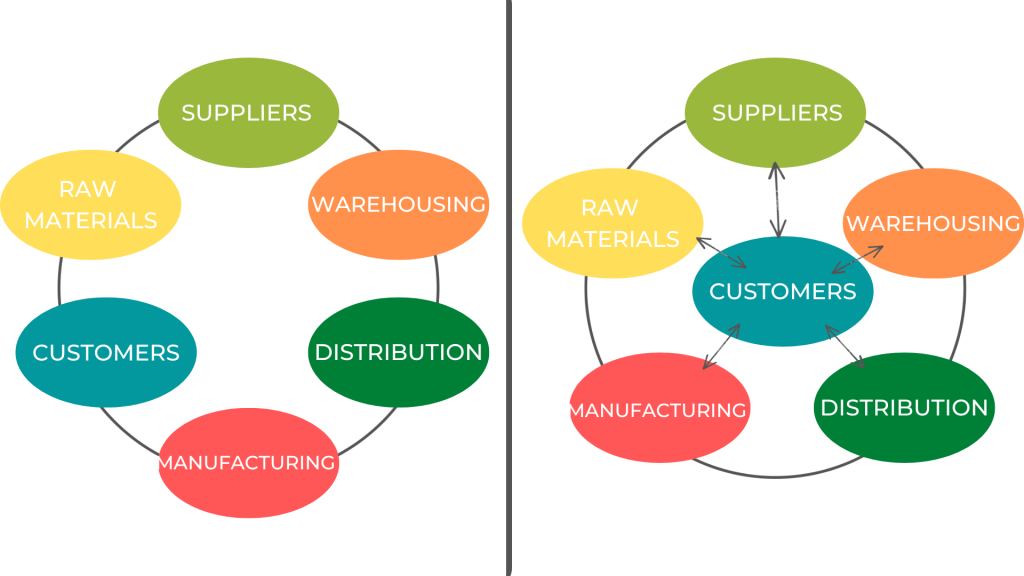

The graphs below show two types of supply chains, the traditional supply chain, in which the customer is at one side, as its function is to receive the service, and on the other side, the customer-centric supply chain.

- Suppliers use predictive analysis based on the purchasing patterns of their customers to determine the amount of raw materials needed at any moment.

- Warehouse planning depends on a thorough analysis of the purchasing patterns and information from your stock, suppliers, warehouses and market trends.

- In the manufacturing process, customer feedback and market trends are used to improve quality and stimulate innovation, making production increasingly customer-driven.

- Customers have multiple distribution channels to choose from at their convenience, such as in-store pick-up, home delivery, pick-up point delivery, one-day express delivery, and more.

In addition, the newest technological developments should be taken into account, as these can be a strong differentiator, for example, real-time tracking, automated factories, drones…

Starting with a customer-centric logistics system is costly, as you have to invest time in analysis and research, as well as monetary investment, and it can be stressful and exhausting, but in the long-term the benefits will be much greater and the competitive position will be higher.

References:

B. (2017). What is customer centricity? Arrizabalaga Uriarte Consulting. https://arrizabalagauriarte.com/en/que-es-el-customer-centricity/

Bolumole, Y., Grawe, S. J., Caltagirone, J., & Daugherty, P. J. (2021). It’s time to adopt a customer-centric attitude. Scmr. https://www.scmr.com/article/its_time_to_adopt_a_customer_centric_attitude

Pedersen, M., Pitts, B., Reiss, M., & Simmons, S. (2020). The four characteristics of a customer-centric supply chain. CSCMP’s Supply Chain Quarterly. https://www.supplychainquarterly.com/articles/4062-the-four-characteristics-of-a-customer-centric-supply-chain

Tom, K. (2020). The importance of having a customer customer-centric logistics system. Latest Supply Chain Trends | Logistics & Fulfillment Blog. http://www.leansupplysolutions.com/blog/importance-customer-customer-centric-logistics-system/

Unknown. (2016). Customer-centric supply chain planning: The difference is in the details. Supply Chain Link Blog – Arkieva. https://blog.arkieva.com/customer-centric-supply-chain-planning-detail-differentiatio