In the activity of our last logistics class we got in contact with an environment that best can be described as VUCA. For me the term VUCA was completely new and I wanted to know it’s meaning. This blog post is addressed at those that, just like me, are unfamiliar with the term and want to obtain an understanding of it.

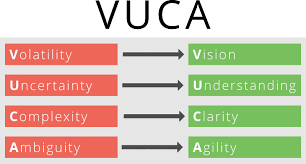

The acronym VUCA comes from the American military and describes the highly demanding conditions in war zones, where nothing could be predicted and everything could change from one day to the next. The term VUCA has been adopted to project management as well as general corporate environments because most of the time these conditions are also common in these business environments. VUCA stands for:

- VOLATILE – change is rapid and unpredictable in its nature and extent.

- UNCERTAIN – the present is unclear and the future is uncertain.

- COMPLEX – many different, interconnected factors come into play, with the potential to cause chaos and confusion.

- AMBIGUOUS – there is a lack of clarity or awareness about situations.

HOW TO DEAL WITH A VUCA ENVIRONMENT?

In order to deal with VOLATILITY a clear VISION is needed for orientation when it feels like everything is changing around you. So define your vision and make sure you and your project staff always keep it in mind.

UNCERTAINTY can be countered with UNDERSTANDING. Information is needed to make decisions. So make sure there is a way to exchange knowledge between all participants. Additionally, you should also deal with risks early on and conduct detailed risk management.

React to COMPLEXITY with CLARITY. Provide clear direction, communicate clearly and try to design processes as simply as possible.

Fight AMBIGUITY with AGILITY. Ensure cooperation and communication between all project participants. Working agilely makes this simple, for example, by having a daily Scrum to keep everyone up-to-date.

As Logistics is defined by the flow of information and goods, dealing with a VUCA environment is definitely an important part of any logistics manager’s day-to-day business. I hope this post brought some clarity about the meaning of VUCA and some of you can benefit from it. Detailed information can be found here.