In today’s globalised world recent advances in information technology have resulted in one of the century’s most important trends: big data. Big data, in a nutshell, is the phenomenon in which businesses collect massive amounts of data from a variety of sources, including enterprise resource planning systems, customer relationship management systems, orders and shipment logistics, customer purchasing patterns, and product lifecycle operations.

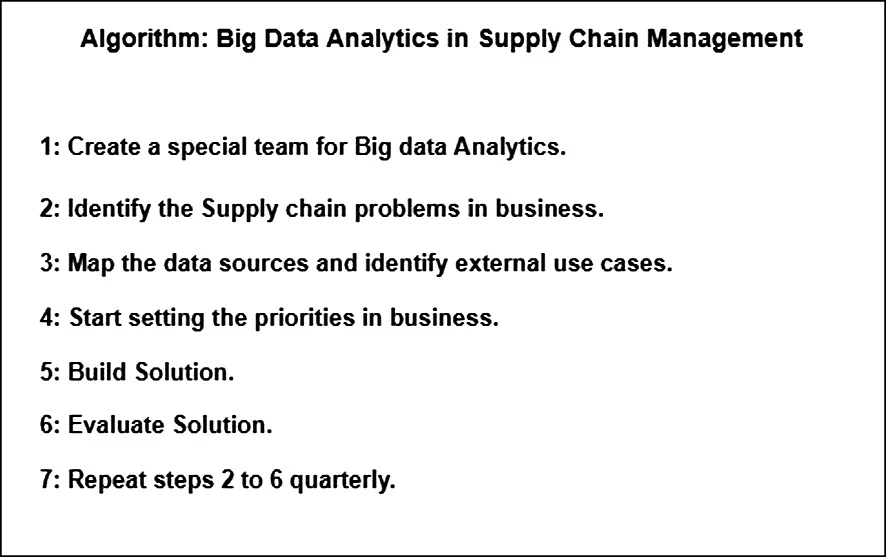

The first stage in integrating Big Data Analytics (BDA) into an existing corporate supply chain, as shown in Image1, is to put together a team of capable big data experts. A member of this team must have a combination of exceptionally deep analytical abilities and the ability to work with unstructured data, as well as a thorough awareness of the company’s supply chain.

The second phase, as indicated in the image above, is to identify supply chain issues. The BDA team must first comprehend existing company goals and performance gaps in order to create viable solutions. Any delivery or demand forecasting problems, as well as out-of-stocks for a given vendor, would be some of the areas of interest. Product reviews may also be used to enhance future releases using BDA procedures.

The third stage is to map out the sources of information and determine the data type (structured or unstructured). It also entails looking for external use cases. Looking for current reusable solutions might be a good place to start when brainstorming alternative ideas. These concepts might come from your rivals, professional groups, or software vendors.

The fourth phase in the process is to establish business priorities. Once you’ve compiled a list of good ideas and relevant data sources, you’ll need to generate an estimate for each idea’s solution, which includes the cost, implementation feasibility, and potential gain from that solution.

The fifth phase in the process is beginning to construct solutions based on the priority list generated in the previous step. The end-user must be involved in the solution development process on a frequent basis and provide input to guarantee that the solution addresses the underlying issues that would otherwise be overlooked. A rapid technique to have basic prototypes ready in a matter of hours are “Hackathons”. As the solutions are fine-tuned in response to user feedback, they be come more trustworthy and can be reliably provided to end users once finished.

Once the solution is complete, the effect of the solution must be assessed in order to fully comprehend the product’s influence. The results may be compared to the goals that led to the creation of the solution.

Finally, an evaluation of the solution has to be performed, depending on the intricacy of an idea, evaluation may occur in iterations. Business impact and proven hypotheses are among the assessment criteria. Based on the evaluation results, the stakeholders decide on the next step. The following phases might include expanding the concept, fully implementing the concept, or releasing the completed product.

Given these points, it is evident that the benefits of employing big data analytics in SCM may be much enhanced since the company will be able to estimate their requests in advance and the amount of complaints about product quality, out-of-stock difficulties, and packaging concerns will be greatly decreased. The overall cost of product development would be reduced.

Finally, I would like to leave a video explaining some of the applications of big data in supply chain management.

References:

https://link.springer.com/chapter/10.1007/978-981-19-0240-6_3

https://www.ingentaconnect.com/content/mcb/ijlm/2001/00000012/00000002/art00002